Pharmaceuticals Distribution

Pharmaceutical Manufacturing Process

Pharmaceutical Manufacturing Logistics Solutions.

Relentless Control.

Absolute Confidence.

Logistics Tailored for Pharmaceutical Manufacturing.

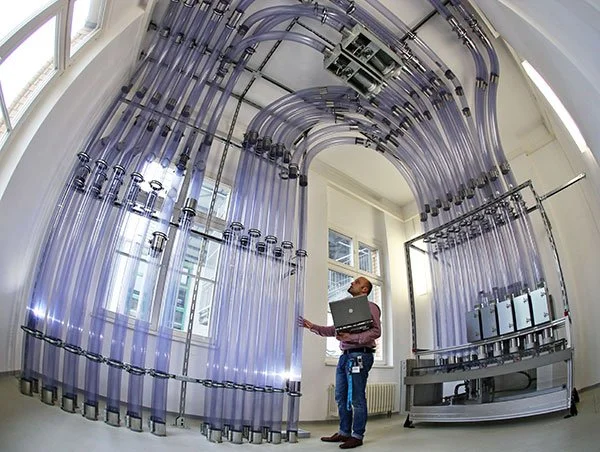

Eliminate cross-contamination, ensure compliance, and accelerate production with Aerocom’s proven pharmaceutical manufacturing solutions, including advanced pneumatic tube systems designed for CDMO pharma facilities.

Imagine a sterile, state-of-the-art pharmaceutical production floor where automated systems integrate with skilled personnel and precision equipment seamlessly. This synergy enhances drug development processes and optimizes every aspect of your operation.

The Cost of Uncertainty in Pharma Operations

When Every Second—and Every Sample—Matters

Pharmaceutical manufacturers face relentless demands: maintaining sterility, ensuring traceability, and guaranteeing workflow continuity. With increasing output, tightening regulations, and uncompromising quality standards, every moment counts.

Nonstop Regulatory Pressure

Maintain FDA, EMA, and global GxP compliance at all times.

Operational Bottlenecks

Waiting on material movement creates costly downtime across production lines.

Risk of Contaminants

Manual handoffs increase risk, potentially derailing entire batches.

Escalating Oversight

Audits demand detailed proof of every action, every transfer, every shift.

Atreo Solutions: Engineered for Controlled Environments

Purpose-Built Systems for Seamless, Compliant Pharma Workflows

Atreo's pneumatic tube systems and process consulting are engineered to elevate drug production facilities and pharmaceutical plants, delivering measurable operational advantages:

Pneumatic Tube Systems—Pharma Safe Series:

Accelerated Sample Transport

Rapidly move raw materials, samples, and finished products between labs and production lines, as well as quality control, minimizing wait times and expediting batch release.

Chain-of-Custody, Secured

Essential Automated tracking and reporting for every movement—critical for batch records, compliance, and regulatory audits.

No-Disruption Integration

Systems designed for cleanrooms, hazardous areas, and high-throughput environments, with the capability to adapt to new production lines or facility layouts.

Sterile Transfer, Every Time

Closed-system design maintains product and sample integrity, minimizing manual handling and exposure to reagent contamination risks.

Enhanced Security

Secure, closed-system transport minimizes the risk of loss, theft, or tampering with high-value or sensitive materials.

Sustainability Benefits

Decreased energy consumption and reduced reliance on manual or motorized transport contribute to your facility’s sustainability goals.

Labor Efficiency

Allow customers to focus on automating internal logistics, freeing skilled staff for higher-value tasks and reducing human error.

Reduced Downtime

Quick delivery of critical components and samples minimizes production interruptions and supports continuous operations.

Data Integration

Modern pneumatic tube systems interface with MES and LIMS, streamlining documentation and process control.

Regulatory & Process Consulting

Atreo Quality Control Pneumatic Tubes Solutions

Audit-Ready by Design

Ensure logistics fully align with 21 CFR Part 11, GMP, and data integrity requirements.

Bottleneck Analysis

Pinpoint workflow slowdowns—from sampling to QC to batch release.

Continuous Improvement

Ongoing optimization of pharmaceutical manufacturing solutions to keep pace with regulatory and operational evolution in CDMO environments.

Proven: ROI, Compliance, and Risk Reduction

Performance Validated in World-Class Pharma Facilities

25% Faster Time-to-Release

Reduced testing, QA, and production cycle times.

Zero Lost Batches to Handling Error

Facilities report 100% record retention and traceable transfers.

<1% Contamination Incidents Post-Implementation

Statistically significant drop in preventable deviations.

$750K Annual Savings

Achieved through operational efficiency and reduction in regulatory interventions.

Morris & Dickson - Proud Owner of Pneumatic Tube System for QAQC Emergency Solution.

"Atreo streamlined our lab-to-line movement, and the experience in compliance reporting wins positive marks in every audit."

Director, Global Operations, Multinational Pharma Manufacturer

When Compliance Isn’t a Checkbox—It’s the Standard

Why Pharmaceutical Leaders Choose Aerocom

1. Built for GxP Environments

Systems engineered specifically for pharma and biotech manufacturing realities, integrating advanced pharmaceutical manufacturing solutions to enhance drug production efficiency.

2. Unmatched Data Integrity

Automatic documentation to satisfy every auditor, internal and external.

3. Scale Without Compromise

Solutions adapt to multi-site, high-volume environments with zero disruption.

Pneumatic Tube Slide Rail Receiving Station

Ready to Transform Your Plant?

Turn Compliance into Competitive Advantage