Insights & Strategies for Smarter Operations and Lasting Impact

Choosing Pneumatic Tube Systems for Hospitals: 7 Requirements Facilities Teams Can't Ignore

Selecting pneumatic tube systems for hospitals is not like buying a copier. This article outlines seven requirements facilities, planning, and operations leaders should build into every RFP—from designing around clinical pathways and station placement to safety validation, data, reliability, and vendor partnership—so the hospital tube system staff receive actually works for real care workflows.

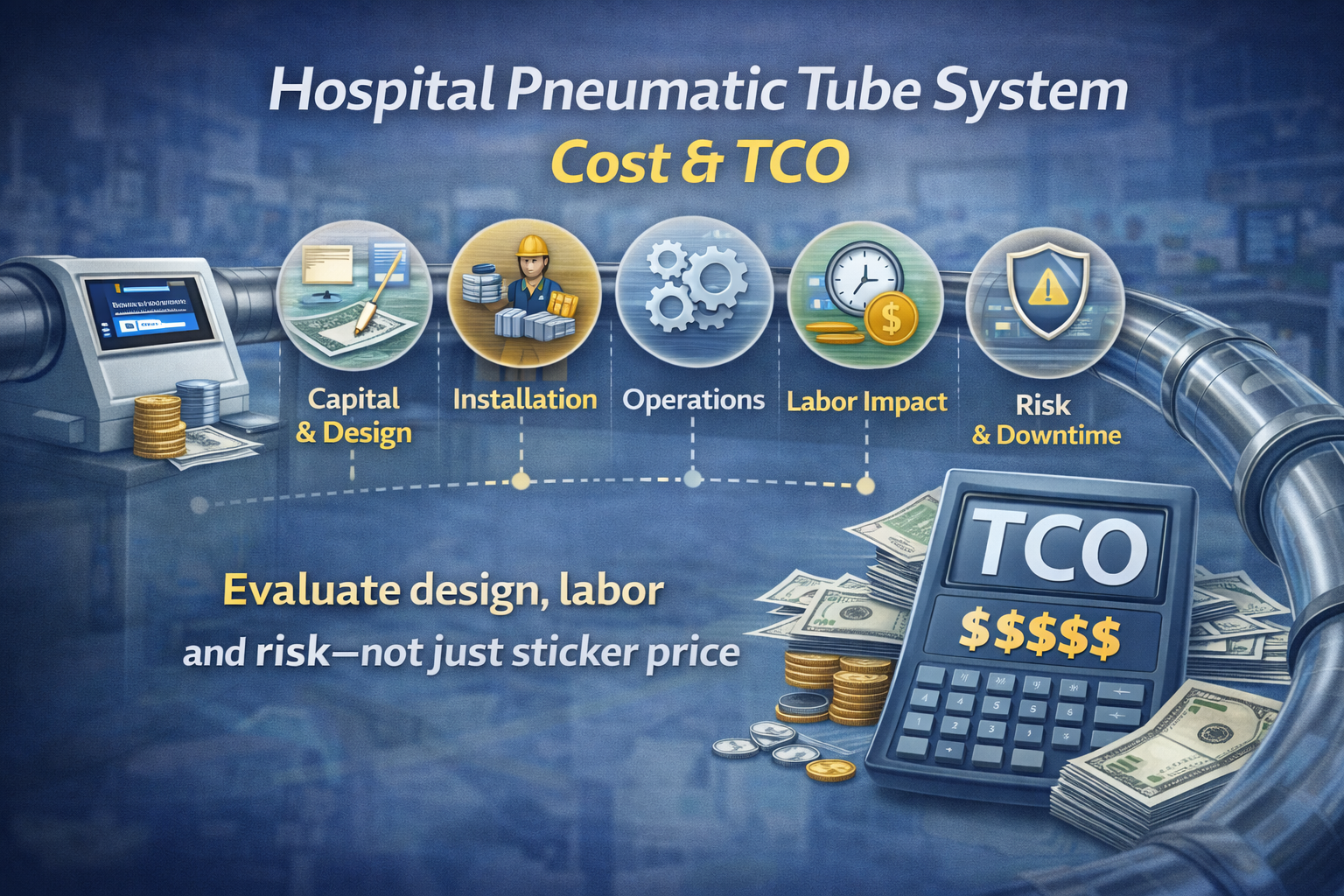

How Much Does a Hospital Pneumatic Tube System Really Cost Over Its Lifetime?

Sticker price only tells part of the story. This article breaks hospital pneumatic tube system cost into five layers—capital, installation, operations, labor impact, and risk—so CFOs, COOs, procurement, and facilities leaders can compare true total cost of ownership against the cost of “doing nothing” and choose designs that deliver real long‑term savings.

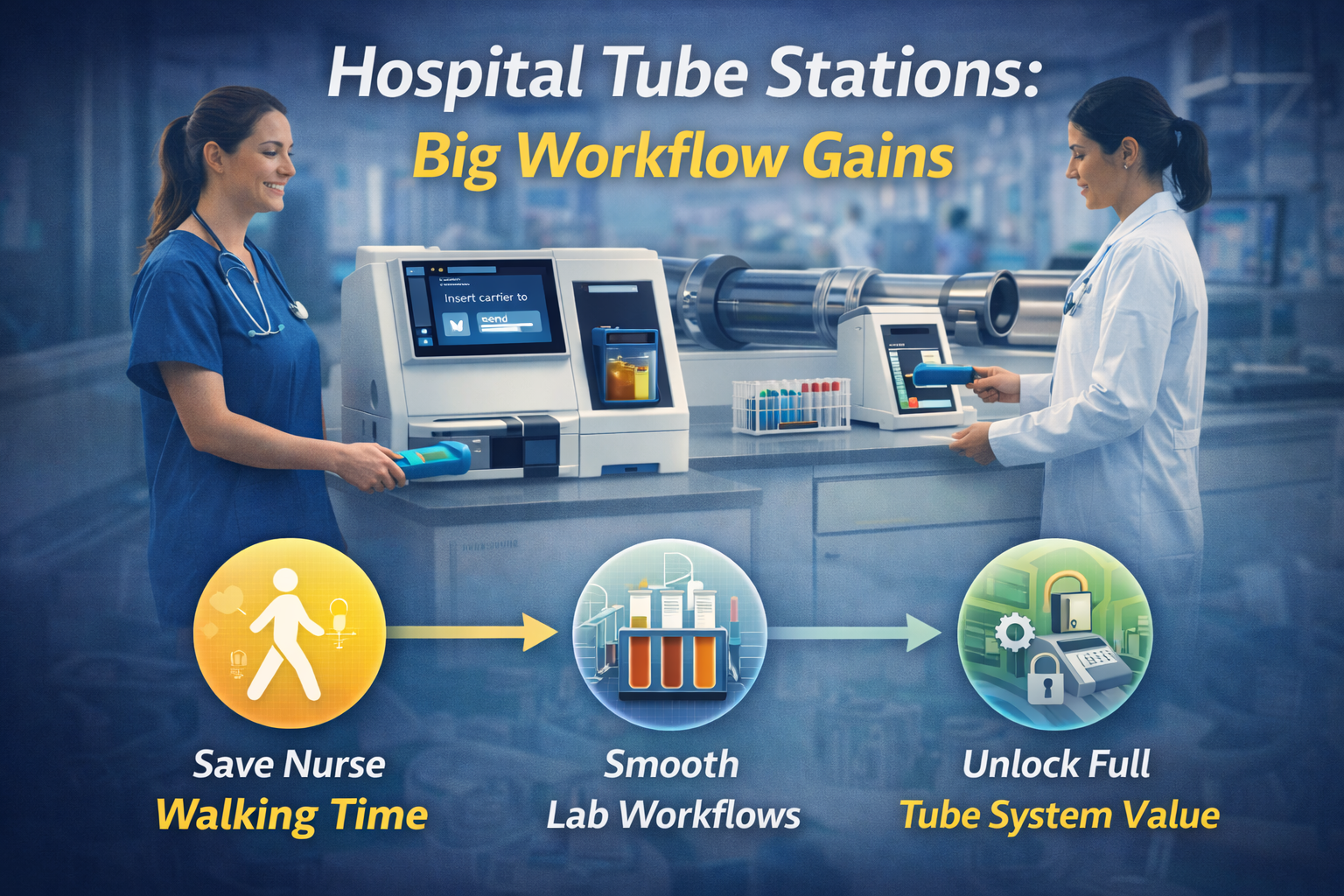

Hospital Tube Stations: Small Footprints, Big Gains in Nurse and Lab Workflows

For nurses and lab staff, the “system” they experience every shift is the hospital tube station, not the pipes behind the walls. This article shows how station placement, design, and ownership affect nurse walking time, lab TAT, and trust in automation—and offers practical, station‑level fixes that deliver outsized workflow gains.

Tat Time vs. Turnaround Time: What Hospital Leaders Actually Need to Measure

“TAT time” complaints often lump together ordering, blood collection, transport, lab processing, and clinician action into one vague number. This article explains what TAT actually means in the lab, why tat time laboratory metrics can mislead, and how hospital leaders can break TAT into clear components to find and fix real delays.

What Does 'Laboratory Connection' Mean in a Modern Hospital?

“Laboratory connection” isn’t just how samples reach the lab. It’s the full chain—from orders and labeling to transport, automation, and result delivery—that shapes turnaround time, clinician trust, and patient care.

Safety Audits: Reducing Risk with Automated Tube Systems

Regular safety audits of automated hospital tube systems help you spot risks before they cause incidents, protect specimens and medications, and prove compliance with safety standards.

Transporters in Hospitals: Who Owns the Journey of Critical Items?

In many hospitals, everyone assumes someone else is moving critical items. This article examines transporters in hospitals—nurses, porters, pneumatic tube systems, and couriers—and shows operations and clinical leaders how to clarify ownership, reduce hidden nurse workload, cut delays, and make internal logistics a reliable part of patient care instead of a guessing game.

Building a Lean Hospital Transport System: From Porters to Pneumatic Tubes

Internal transport is often an invisible source of delay and waste. This article shows operations leaders how to build a lean hospital transport system, matching porters, routes, and pneumatic tube transport to clinical demand so specimens, meds, and blood products move faster, staff walk less, and turnaround times become more predictable.

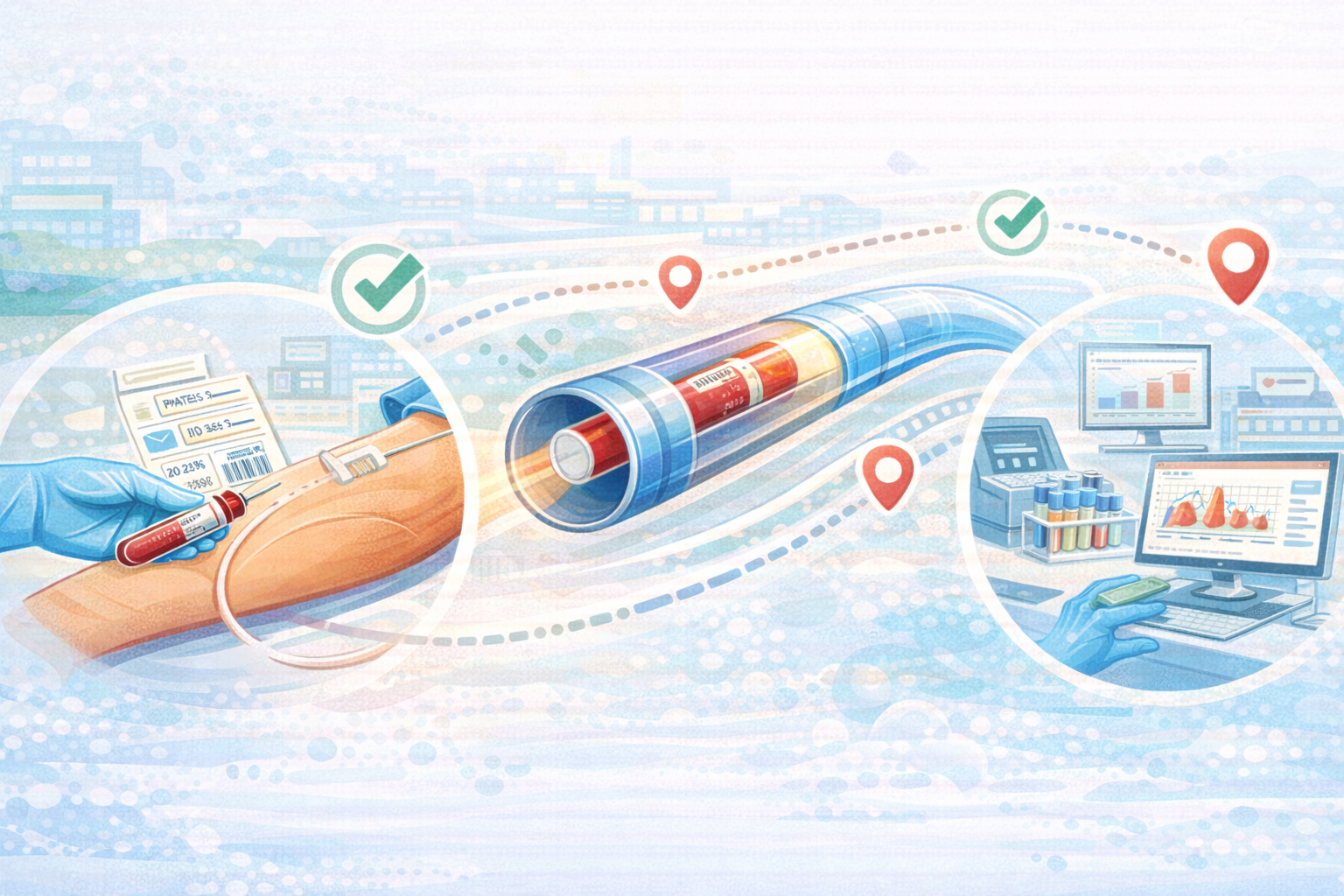

From Vein to Result: The End-to-End Journey of a Blood Sample in the Hospital

A blood test result is the end of a much longer story. This article traces the full “vein to result” journey in hospitals—from blood sample collection and bedside labeling to laboratory transport, pre‑analytical processing, and analysis—so operations and lab leaders can see where time is really lost and how to improve turnaround time and quality.